Our services

Get to know what we do

Materials

With our years of experience in fabricating with Homo/Copolymer Polyprop, PVC, PVDF, ABS, HDPE and CPVC, we can advise on the best and most suitable material for your particular application.

We specialise in the manufacture and installation of all types of chemical resistant polymers for pipework, tanks, ducting systems etc. and can advise on current standards which may apply.

We use up-to-date welding technology to carry out all types of welding, whether it’s hot gas welding, extrusion welding and for pipework systems, heat socket weld / Butt fusion / Infrared welding (I/F) and bead and crevice free welding.

We have a large number of reputable suppliers, sourcing from their large distribution centres. Materials that are required whether in stock at Marcol or need to be called in, will be planned into our lead times for products to be built and delivered at the agreed delivery date established with the customer at the time of ordering.

Design

We offer a full design service for outline schemes, detail drawings, and specification. This can include materials, manufacture, methods of installation and conformity to appropriate standards.

We will work closely with you, providing continued feedback and improvements throughout the design stage of a project.

Our trained and experienced engineers are on hand to visit you at your place of work or on site, whether it is a simple pipe installation or a detailed and complicated manufacturing project.

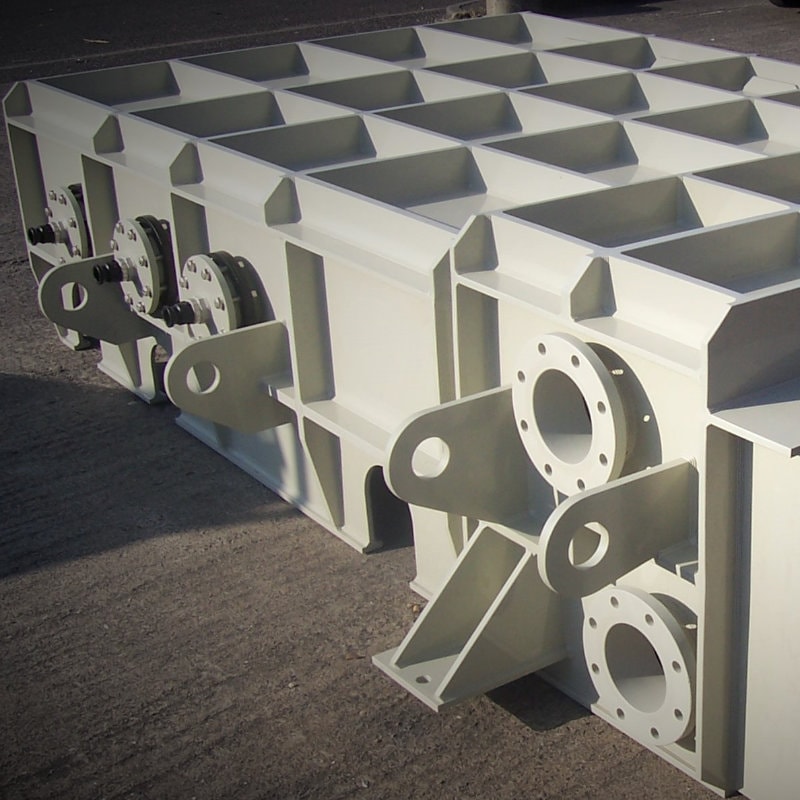

Manufacture

We are happy to work from customers’ existing drawings, or if you require, we are able to produce our own 3D manufacturing drawings. With over 30 years of experience you can be sure that we will provide a high level of quality and workmanship throughout the project. Using ITP’s (“Inspection and Test Plans”) and QCP’s (“Quality Control Plans”), which allows our customers and ourselves to monitor projects throughout the manufacturing process and at the end of the project, carry out a FAT (“Factory acceptance test”).

For small bespoke systems, many clients are looking to have their equipment skid mounted prior to being delivered to site. This reduces the on-site labour costs considerably. We can produce drawings for approval from something as simple as a P&ID (“Process and Identification Diagram”).

Skid systems have the advantage of having all equipment installed, tagged and all tested, long before coming to site.

Building equipment off site can offer huge savings against on-site installation cost.

Installation

We have qualified and skilled engineers working out of our factory and on customers sites. A fully equipped installation team will go wherever needed to install your products. Adaptable and resourceful, they are equipped to travel throughout the UK and abroad. All our staff are fully qualified and trained for the tasks undertaken by them working strictly to RAMs (“Risk and Method Statements”). Any specific site requirements obtaining to a customer’ will be incorporated into documentation specifically issued by project.

Health and Safety is of absolute paramount of importance to Marcol. We ensure that all our employees are fully trained in any equipment they use, where necessary sending them on external courses to obtain recognised qualifications. In addition, our fabricators/installers are holders of CSCS cards and also hold CCNSG client/contractor national safety passports, many of them at supervisor level. Supervisors are also fully first aid qualified.

Modifications, service and repairs

During a project you may need to make changes, or improvements. Installations require routine maintenance to ensure continued operation and safety for the operator. Routine maintenance can highlight a number of potential hazards that should be addressed before a problem arises and damaged or broken components must be repaired or replaced, which could be very costly.

With the knowledge gained by Marcol’s sales team over the years working with clients in all types of industry, identify issues before they arise is something we are more than happy to come to site and offer, whether it’s just a simple visual inspection or a written report detailing any preventative action required, or even possible improvements.